Dueker gate valves – for water and gas.Reliable, safe and cost-effective.

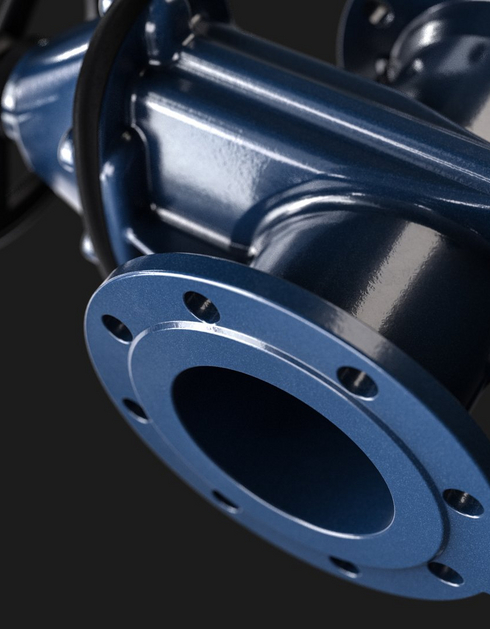

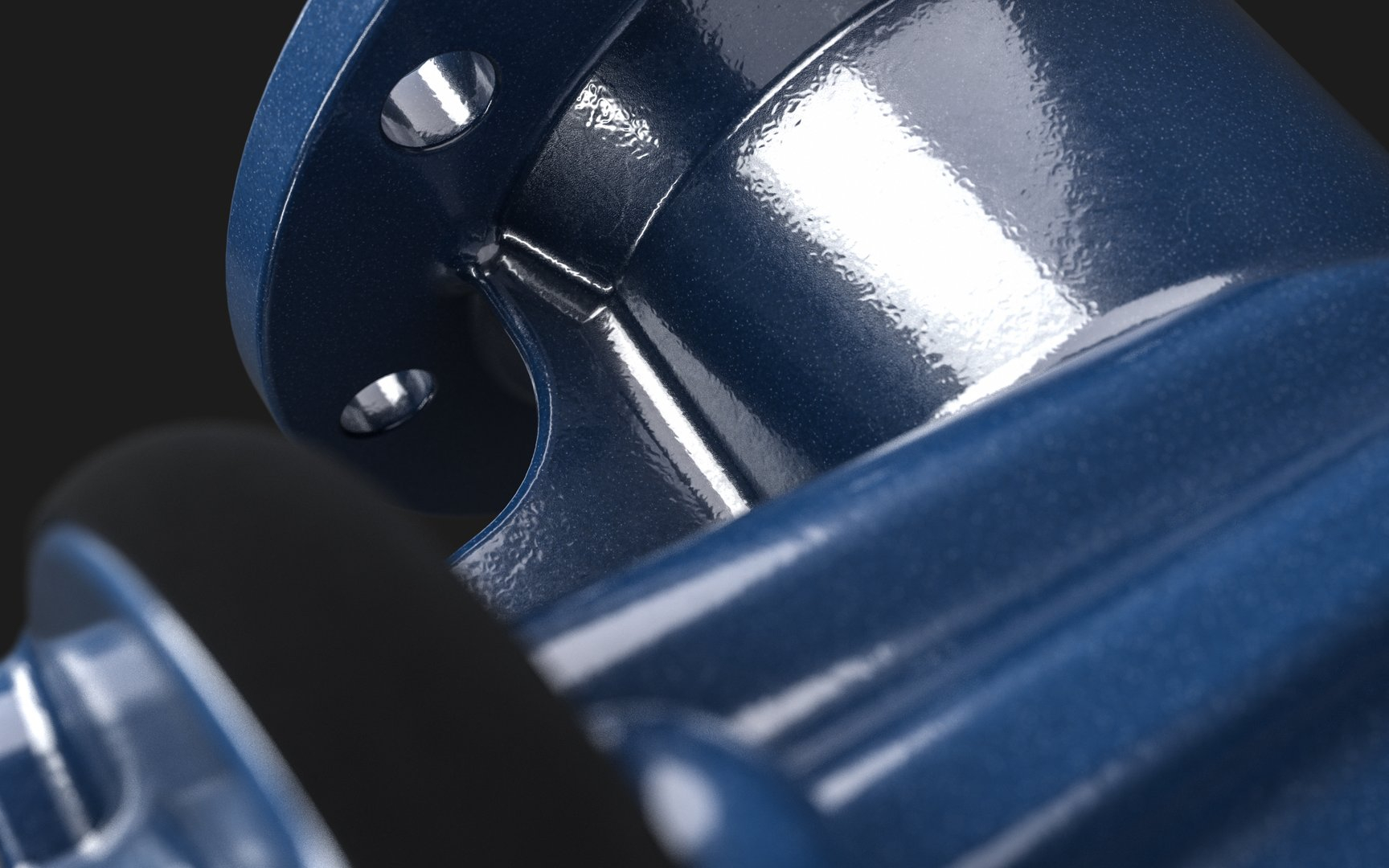

Dueker gate valves are used to great effect all over the world. There is a good reason for this – valves have to meet high requirements, especially in the drinking water sector. Dueker gate valves do precisely this. This is because they have been developed with the highest skill and are manufactured from ductile cast iron with the greatest care. Either fully enamelled or with an epoxy powder coating, they only leave our premises once they have been rigorously tested.

Gate valves

Type 2004 and 4004 replacement and repair gate valve.For removal or quick replacement when needed.

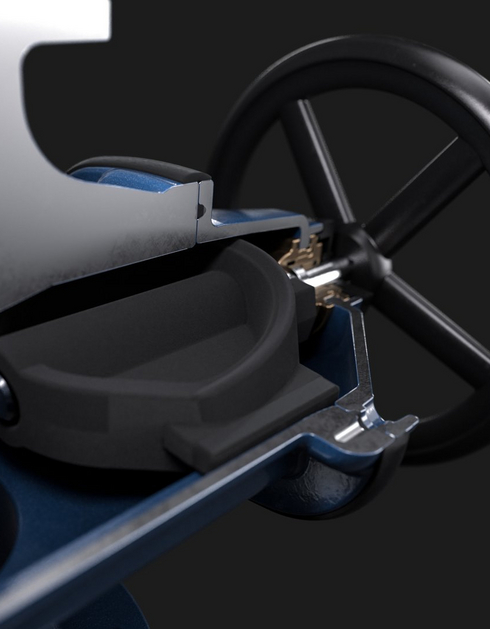

These gate valves open up real opportunities for all plant and pipe network operators. The basis of these valves is the tried-and-tested Dueker repair gate valve concept. This series is available in nominal diameters from DN 80 to DN 200 and is characterised by a multitude of innovative details. The loose flanges, for example, can be extended by 4 mm on both sides within a certain tolerance range and are tightly connected to the body. The omission of the flange gasket on the loose flange sides results in additional play, which is compensated for by the movement of the loose flanges. The seal itself is integrated in the loose flange.

More examples? If the worst should happen, the valve can be replaced quickly and easily. Misalignments on an existing pipeline can be easily offset. There is no need to make room between the pipe and the valve to install the sealing ring.

This tried-and-tested concept allows you to use your resources cost-effectively. Whether it is for a new construction project or for the renovation of plants and supply networks. Depending on the material selected for the dismantling joints, savings of between 5% and 20% can be made for a new investment.

Gate valves

In summary.Gate valves at their best.

If you are looking for gate valves with a long service life, Dueker gate valves are the answer.