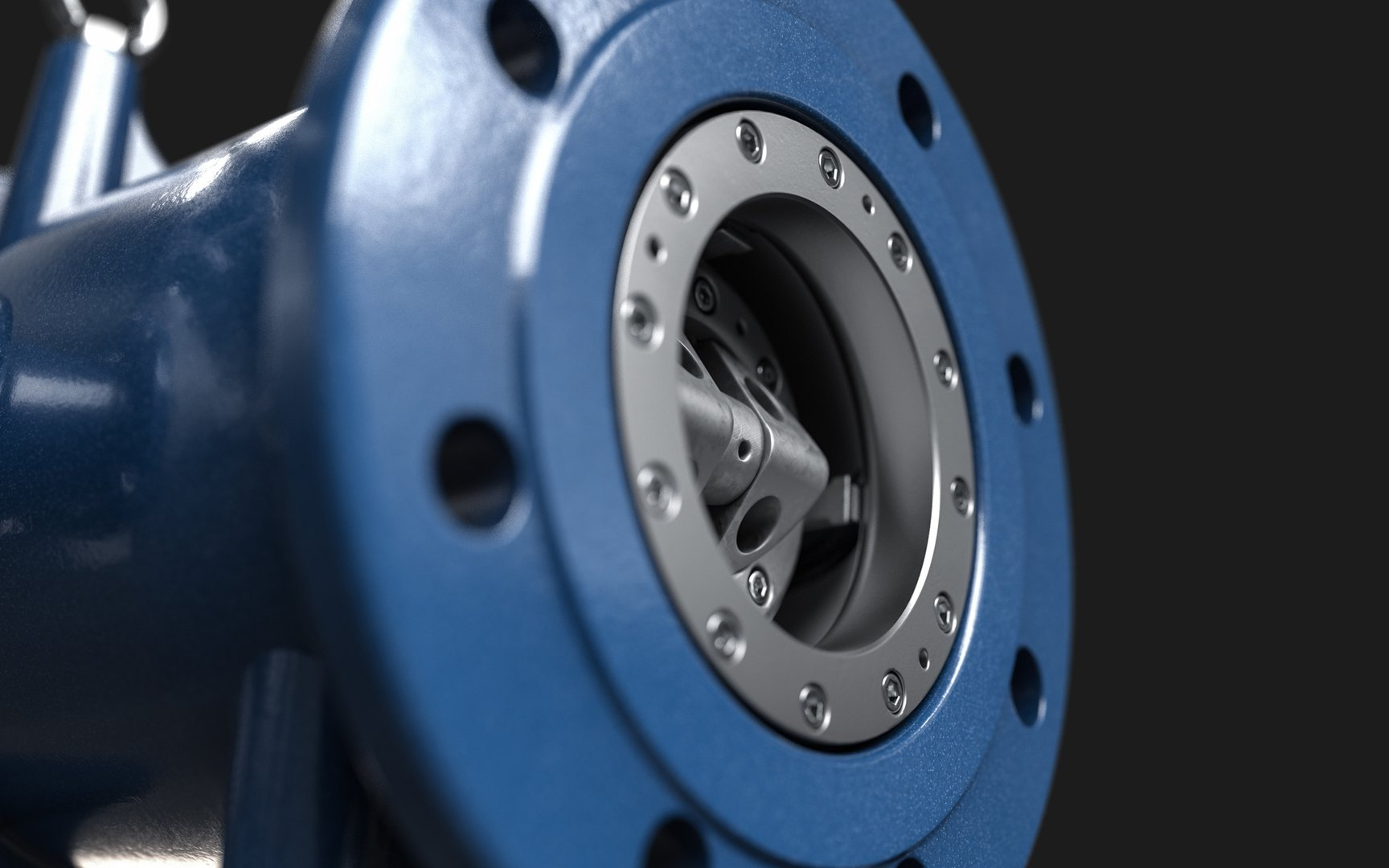

Dueker plunger valve type 7015 – your control valve.Robust, reliable and incredibly precise.

Dueker plunger valves – these are robust and reliable control valves that you can use to precisely adjust pressure and flow rates. Optimum adjustment to operating conditions made easy. They are characterised by precise and very gentle opening and closing, which prevents pressure surges when starting up and shutting down pipelines. These valves can even be used continuously in cavitation-prone conditions. The prerequisite for this is a professional design, which we would be happy to provide.

Plunger valve

The advantages of a Dueker control valve.Easy to adjust, wear-free and durable.

The Dueker slider crank mechanism gear makes the optimum control range very easy to adjust and extremely soft closing possible. The main seal is secure, reliable and largely wear-free thanks to a robust, intelligently positioned profile sealing ring on the piston and an O-ring in the body. The valve is hygienically clean thanks to targeted flushing of the piston and the secure shaft seal. Carefully positioned guide rails guarantee a long service life. Cavitation damage to the valve and pipe is eliminated as cavitation is safely directed into the centre of the pipe.

Plunger valve

The design.Intelligent, hygienic and simply flawless

The highlight is the design: the back of the piston is precisely flushed when the valve is open, while openings allow flushing in the front piston bearing. This prevents stagnant water from forming. Germs don’t stand a chance. Other positive effects: the body O-ring is protected against unnecessary wear as it only seals around the piston when closed. Thanks to the openings in the piston bearing, negative pressure cannot form behind the piston, meaning it can be moved easily at any time. The main seal is not in the seat ring, but on the piston instead. This protects it from the flow – and from the associated wear.

Plunger valve

The variants. It’s all a matter of design.

We offer different versions of the Dueker plunger valve. With a seat ring, slotted cylinder or perforated cylinder in different shapes depending on your operating conditions. With the Dueker slider crank mechanism gear and hand wheel, with an electric actuator or with a pneumatic or hydraulic rotary actuator. You can also get it with different gear positions depending on the installation. Currently available in the dimensions DN 150, 200 and 300 with nominal pressure PN 10 to PN 40. Further dimensions DN 250, 350 and 400 are being developed.

Plunger valve

The guide rails.Made of high-strength stainless steel – for every installation position.

At least eight rails made of high-strength stainless steel guide the piston safely into any installation position. These guide rails are firmly anchored in the body without any screwing or welding. Problems associated with screwing and welding therefore do not occur. As the guide rails are made of a harder material than the piston, any wear on the material is limited to the piston, which runs smoothly again after a brief rotation. After several rotations, the piston can be easily replaced directly on site. There’s no need to send it back to the plant!

Ringkolbenventil

Any questions? Get in touch.

If you want to know more about the body, the gearbox, the hand wheel, the design of the piston and the plunger valve or aspects such as pressure differences, take a look at our animation RKV type 7015. Or contact us directly.

Plunger valve

In summary.Get things under control.

There is always a way to control water. One of the best is still the plunger valve by Dueker.