Dueker non-slam check valve type 8015 – your check valve.Reliable, hygienic and hydraulically optimised.

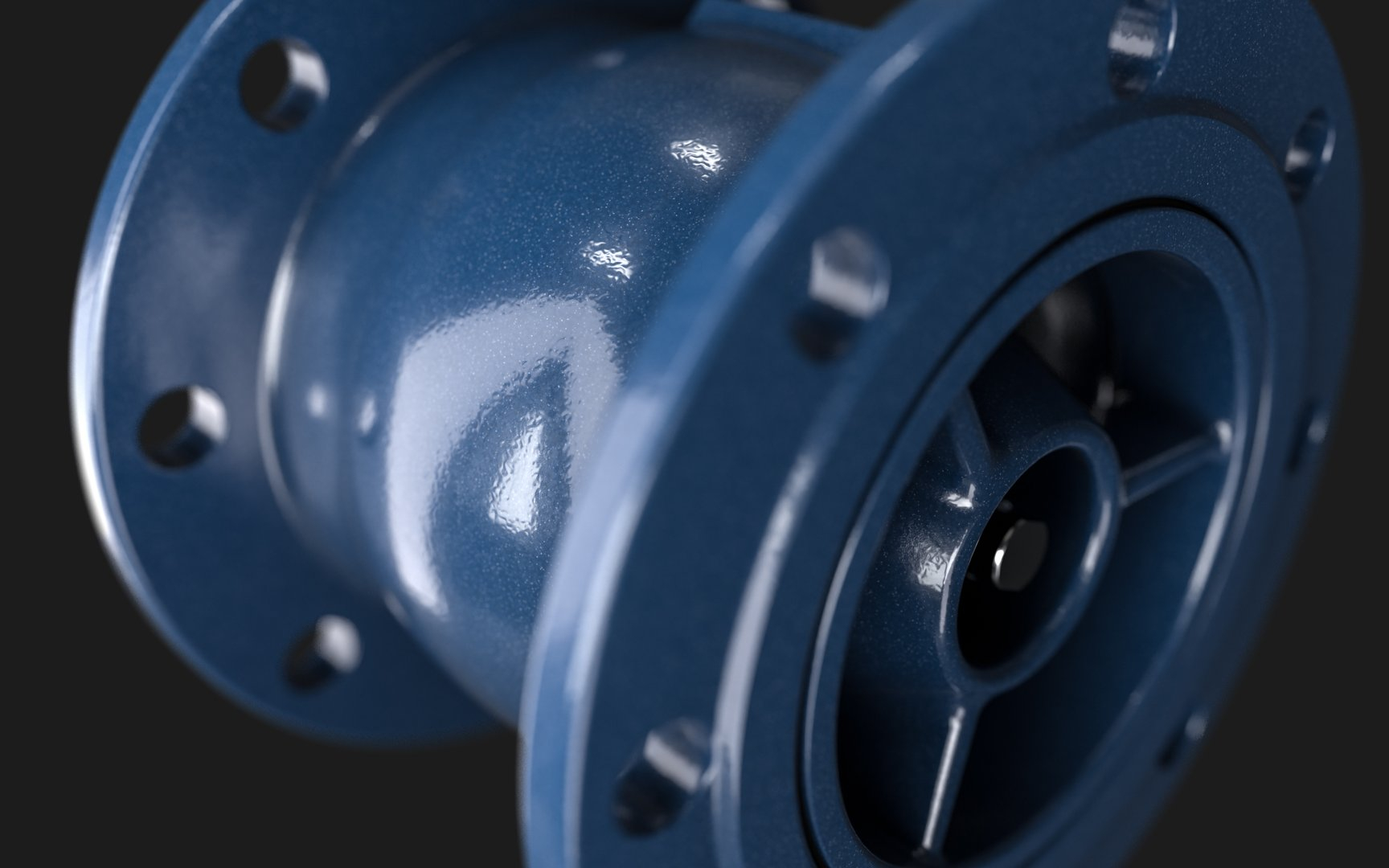

It is fully enamelled and free of non-ferrous metals, available in the dimensions DN 80 and DN 200 with a nominal pressure of PN 10/16 or 25/40: the Dueker non-slam check valve type 8015, resilient-seated with a central valve disc. Designed for drinking and untreated water up to 60 °C, with a face-to-face length according to EN 558 basic series 14 and DVGW-registered (German Association for Gas and Water Applications), it is your reliable check valve. Perfect for all projects in which water should only flow in one direction: to the consumer.

Non-slam check valve

The Dueker check valve and its advantages.All good reasons and all convincing.

There is really something for everyone: whether the flow is horizontal and vertical from below or whether it is vertical from above – thanks to computer-aided CFD simulation, the Dueker non-return valve offers you optimum flow conditions in the direction of flow at all times. Complete seat impermeability is already guaranteed with a return flow at a pressure of just 0.5 bar. Operating costs are also reduced due to minimised pressure losses. Last but not least, the valve is also exceptionally easy to install. And should it ever be necessary, the valves are just as easy to dismantle and it is simple to change installation positions. Good for planners, users, operators and processors.

Non-slam check valve

Applications.When direction matters.

When it comes to industrial water applications, water extraction, drinking water, untreated water, pumps and pumping stations and much more, Dueker valves are the number one choice – and our check valve is no exception. All materials of parts in contact with the medium comply with the current status of the UBA (German Federal Environment Agency) assessment principles and guidelines.

Non-slam check valve

The design.Robust, compact and simply great.

What sets Dueker’s hydraulically optimised check valve apart is its compact, one-piece and flow-optimised body made of fully enamelled ductile cast iron with a flange connection according to EN 1092-2. The body insert is firmly fixed with spring sleeves, reliably secured and easy to replace. The centrally guided valve disc has a vulcanised seal profile acting as shock absorption. Slotted bearing bushes made of high-quality polymer in the body insert prevent any jamming. And what else? The guide rod and spring are made of stainless steel. The bushing is mounted in the body insert to prevent corrosion. O-rings reliably seal all transitions. And the pressure spring can be adapted to all installation positions.

Non-slam check valve

The materials.High-quality, durable and powerful.

Do you take our materials very seriously? So do we. Here you will find precise data: the body and body insert feature seamless enamelling with Dueker etec enamel – according to ISO 11177 and DEV (German Enamellers’ Association) guidelines, for soil class III. The colour is cobalt blue – similar to RAL 5013. Both are made of ductile cast iron EN-GJS-500-14, as is the additional EPDM-rubberised valve disc. The guide rod and threaded bush are made of 1.4057 stainless steel; the spring is made of 1.4310 stainless steel. The guide bush is made of a special polymer.

Non-slam check valve

Any questions? Get in touch.

If you want to know more about aspects such as flow direction, combining different valves or dimensions or anything else about the return flow of drinking water and its prevention – ask us. We will be happy to tell you all about the advantages of our check valve.

Non-slam check valve

In summary.Anything but ordinary.

For some it may simply be a CV, for most it is a check valve. For us, it is our Dueker non-slam check valve type 8015. Top class rather than 0815.