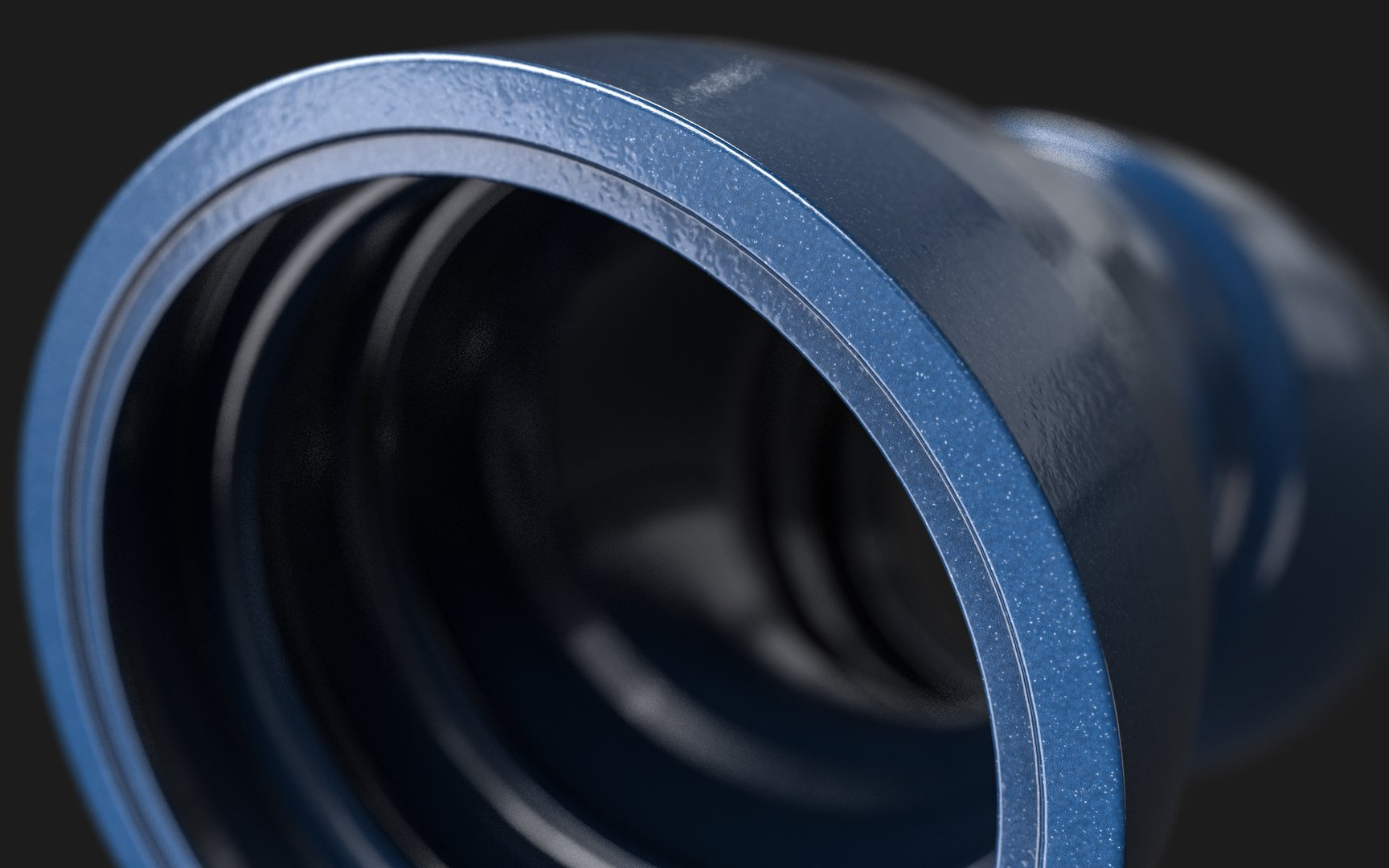

Dueker socket coupling – flange-free and reliable.Cost-effective and efficient couplings.

Fewer tools, faster installation – the flange-free socket coupling by Dueker using push-in socket and axial restraint systems are cost-effective and efficient. For the secure coupling of cast iron pipes, fittings and valves to one another or to plastic pipes – even with high internal and external pressure or in the event of longitudinal displacements due to ground movements and traffic loads. This is because our couplings simply go with the movement without transferring the bending moments to adjacent fittings and pipes. Get rid of the flange with our push-in socket systems. And if the worst should happen, most couplings can be dismantled almost as quickly as they were put together.

Socket coupling

Dueker SMU axial restraint.Seals securely with a retaining ring and locking rims.

The Dueker SMU axial restraint is a socket coupling based on a retaining ring with locking rims. Shear forces are absorbed via this ring. The sliding chamfer attached to the screw ring generates a radially acting force with the retaining ring, which results in secure locking with the spigot. At the same time, an axially acting force is transmitted undiminished to the sealing ring via the sliding ring, which achieves the required sealing effect. Perfect for coupling grey cast iron pipes to modern pipe materials. The system is available in nominal diameters from DN 40 to DN 65.

Socket coupling

Dueker SPEZIAL.The thrust-resistant screw socket coupling

Dueker SPEZIAL facilitates the thrust-resistant end coupling of push-fit EU and U fittings. With Dueker SMU sealing comes first and then the locking occurs independently. The axial restraint system fulfils all requirements, has stood the test of time and is available in nominal diameters from DN 80 to DN 400.

When laying, please always observe our Installation instructions!

Socket coupling

TYTON® SIT® and TYTON SIT PLUS®With vulcanised locking elements.

TYTON® SIT® is a Dueker development which transforms an unsecured TYTON® coupling into an impermeable, secure, shear-resistant socket coupling. The highlight of this internal axial restraint is a special sealing ring with vulcanised locking segments made of corrosion-resistant chrome steel. The individual segments rotate in the area surrounding the clip-in bead, enabling them to adapt to the pipe tolerances. The wedge-shaped rims of these segments lock into the surface of the pipe, absorbing the shear forces. TYTON® SIT® is available for nominal diameters from DN 80 to DN 400, at an operating pressure of up to 10/16 bar. And if the pressure is even higher, we recommend TYTON SIT PLUS® – with this you are guaranteed nominal diameters from DN 80 to DN 600 and an operating pressure of up to 10/32 bar. Perfect for installation in inner-city areas and for long-distance pipelines.

Socket coupling

NOVO-SIT®.For even larger nominal diameters and even higher pressure.

Would you like a little more? Is your required pressure range even higher? Then there is nothing better than NOVO-SIT®. NOVO-SIT® is a patented further development of the TYTON® socket, which is extended by an antechamber. With this innovative separation of the sealing and retaining function, Dueker has created a universally applicable socket geometry for different pipe materials. Thanks to this separation, each function can be individually optimised. In other words, there is no compromise in favour of one function over the other. The vulcanised, corrosion-resistant chrome steel segments of the NOVO-SIT® sealing ring ensure axial restraint. NOVO-SIT® is available in nominal diameters from DN 80 to DN 800 and an operating pressure of up to 60 bar depending on the nominal diameter.

Socket coupling

NOVO-Grip® IIIPerfect for coupling to plastic pipelines.

NOVO-Grip® III facilitates the efficient assembly of fittings and valves in PE-HD pipelines. The axial restraint that is resistant to tensile forces is based on the two-chamber system of Novo socket technology, which separates the sealing and locking function. When NOVO-Grip® III is installed, a special sealing ring (GKS) is first inserted into the Tyton chamber, which compensates for different external pipe diameters. In turn, the NOVO-Grip® III ring made of plastic is inserted into the antechamber. The ring consists of closely spaced plastic segments that lock onto the spigot of the PE-HD pipe to make it resistant to tensile forces. NOVO-Grip® III is available in the pipe diameters DN 90 / 110 / 160 / 225 and an operating pressure of up to 16 bar. The NOVO-Grip® PVC variant is available for PVC pipes. In DN 200, an extra socket is required!

Socket coupling

Any questions? Get in touch.

You can find out more about Dueker socket couplings and axial restraint systems in our brochures and technical documents. If you have any questions, please do not hesitate to contact us. We will be happy to help.

Socket coupling

In summary.A secure coupling for every scenario.

With a socket coupling from Dueker, your pipes and pipelines are securely connected, whether they are inner-city or long-distance pipelines.